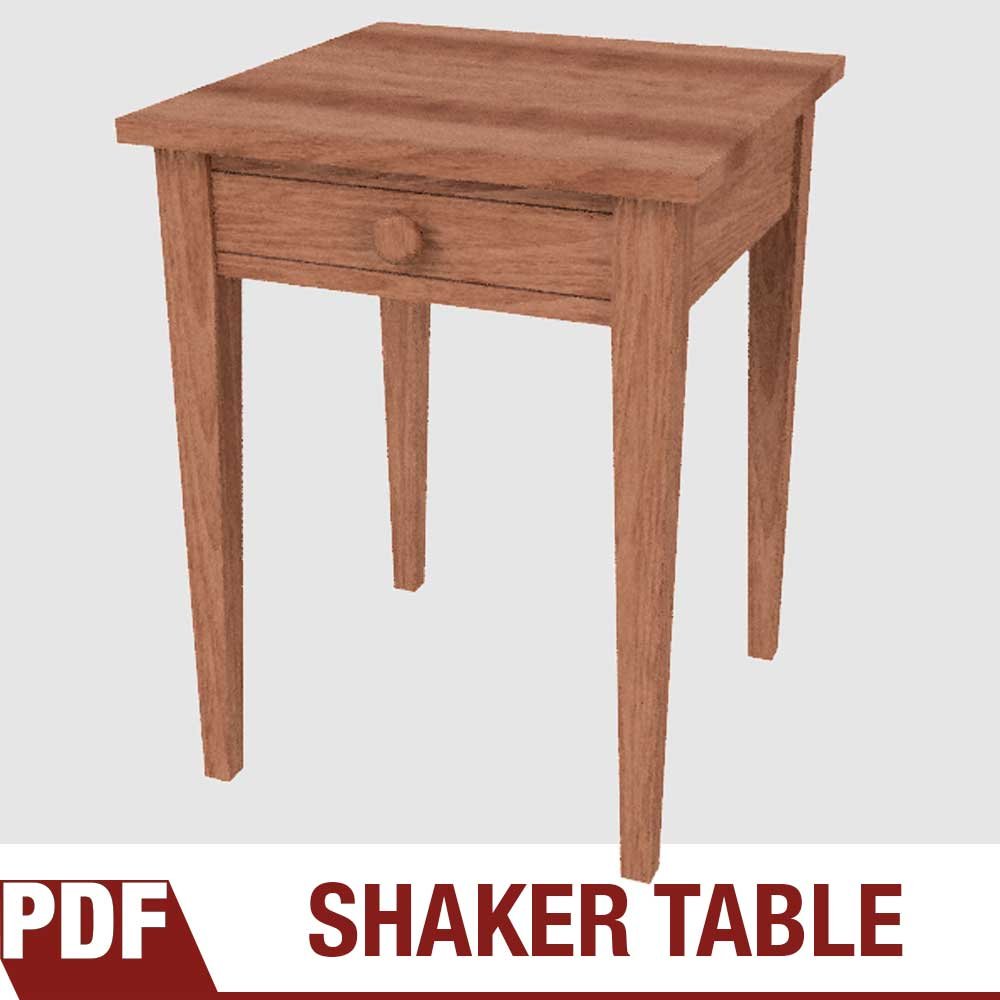

How to Make a Shaker Table

A modern take on a classic woodworking project

A modern take on a classic project. This Shaker table goes together quickly with hidden pocket hole screws. This downloadable PDF is easy to follow with step by step instructions in both imperial and metric.

How to Make High-End Stereo Speakers

How to make high end audio speakers for woodworkers.

CSS Audio Criton 2TD Speaker Kit

How to make high end audio speakers for woodworkers. This project uses the Criton 2TD kit from CSS Audio and makes speaker building a breeze with their custom crossover boards. I knew nothing about speaker wiring and had very little experience with soldering before making these hifi speakers and it turns out it wasn't difficult at all. The crossover boards are designed to make wiring easy for someone like me who doesn't have the knowledge.

Speaker kit provided by Creative Sound Solutions

How to Make Classic Record Crates

Making a modern style wood record crates.

Walnut Wood Record Crates

When it comes to music I am a total nerd. I have a decent vinyl record collection and needed a way to store it and show it off at the same time. I wanted something that looked vintage and thought walnut and hairpin legs were the way to go. The crate and base are two separate parts meaning you can remove the crate and go DJ that next gig. Everything is made from solid walnut and used router cut dovetails for joinery. You can find plans for this project here.

Tools and Supplies Used in this Woodworking Project

Trash to Treasure: Make a Wall Hanging Guitar Amp

Taking an old beat up guitar amp and giving it new life with an updated look and use.

How to Make a Retro Stereo Cabinet

Making a stereo cabinet with a turntable dust cover and record storage.

Making a Vintage Stereo Console

I’ve been wanting to make this retro stereo cabinet for a while now. I spend a lot of time in my basement shop working and wanted to have a turntable in there to play records but also protected from dust. It uses some basic butt joint construction done with loose tenons and made from cherry plywood. The turntable is enclosed with a hinged lid and the stereo component compartments have a removable grill cloth face to keep dust out but allow air circulation.

I did run out of time for a few final details because I’m taking for for a trip. I still need to add some pulls to the front grill faces and lid support or a kickstand to hold the top open while changing records. Once I get back and complete these tasks I’ll post pictures down below and update the steps.

If you make this stereo cabinet please tweet me some pics so I can share it with the world. Thanks for dropping by and as always be safe, be passionate and make something.

Tools and Supplies Used

How to Duplicate a Record

Duplicating a vinyl record using silicon and and resin. A fun lesson in mold making!

Listen to the audio ripped from the duplicated record below.

One of my most fun projects to date! I take a Johnny Cash reissue 7” vinyl record and duplicate it with a silicone rubber mold and liquid plastic. To be quite honest I was surprised on how much detail the mold can handle as the duplicated record played almost perfectly. You can listen to the ripped audio above. There was a few more pops and clicks than the original record and I’m guessing that’s from dust or not cleaning the original enough beforehand. Obviously pirating and duplicating any copyrighted material is prohibited but in the spirit of making and experimentation this was a fun project.

A couple of fun facts about this 7” single: Get Rhythm was the 1956 a-side of this record but it was the b-side that became the huge hit for Johnny Cash. I Walk the Line was the first number one single for Johnny Cash and sold over 2 million copies in it’s original pressing. The copy that I own is a reissue put out by one of my favorite record labels, Third Man Records owned and operated by Jack White.

Original music in the video by Lance Neil Hulsey, Toledo, Ohio

Items Used

Making Acoustic Panels

How to make decorative acoustic panels for your home office or studio.

I record the audio for my podcast and all my voice over work in my office. I recently removed a couch from this room and noticed a significant difference in the audio quality. I was getting a lot more reflection from the walls into my microphone so I’m making these acoustic panels to absorb some of the room sound. I purchased some acoustic foam panels from Amazon and decided to class them up a little bit with a nice wood frame and burlap face. The frame uses a simple picture frame construction with mitered corners reinforced with splines. The face consists of a burlap sack glued to a mitered frame and then screwed on to the base. I purposely exposed the screws and chose to use pocket hole screws for the way they look and how they sit on the surface.

In the video I decided to not voice over the steps but instead talk about how I got to be a YouTuber and all the career changes I’ve made. Making YouTube videos and blogging is a combination of many skills including photography, videography, branding, marketing, audio engineering, graphic design and copy writing.

Please feel free to ask me any questions you may have in the comment section below.

Items and Tools Used

DIY Speaker Build

How to make a speaker cabinet from a wire kit.

In this DIY speaker build I’m using 1/2” baltic birch plywood to make a pair of stereo speakers to look like vintage guitar amps. I’m using orange Tolex on the outside with grill cloth for the face and chrome corner protectors on all the edges. The speaker kit comes from Rockler Woodworking and Hardware and includes all the wiring, base ports, speaker and internal dimension plans. If you want to build the exact same speakers as you see in the video, I have plans for sale in my store and there are links down below to all the supplies needed. You can easily change the look of these speakers but choosing a different color Tolex and grill cloth. This was a really fun and pretty simple project to build. Don’t be intimidated with the speaker wiring. If you purchase the kits from Rocker the plans are easy to follow and don’t take any special tools.

Supplies Needed

- 1/2” Baltic Birch Plywood

- Orange Tolex

- Grill Cloth

- Velcro Squares

- 6 1/2” Speaker Kit

- Front Corner Protectors

- Rear Corner Protectors

- Rubber Feet

- Speaker Wire

Tools Needed

How to Make a Guitar with a CNC Machine

Step by step instructions on how to make a solid body guitar on the CNC using parts from a cheap Epiphone Les Paul.

Step by step instructions on how to make a solid body guitar on the CNC using parts from a cheap Epiphone Les Paul. I purchased my Epiphone Les Paul online for only $120 just to gut it for the electronics, hardware and neck. I used some 8/4 ash for the body and carved out the neck pocket, pickup and electronics cavities on the X-Carve CNC. With an angle grinder and TurboPlane blade I did some final shaping. The pick guard, headstock laminate and truss rod cover was also cut out on the X-Carve CNC using carbide bits from ToolsToday. I’m very please with this guitar build and plan on filming a follow-up video answering your questions as well as discuss what I’d do differently for the next guitar build.

Products Used

Speaker Cabinet Rebuild with Walnut and Hickory

Remaking and up cycling an old pair of Sony speakers with a new wood enclosure.

Speaker Cabinet Rebuild

I got tired of looking at the boring ol’ black Sony stereo speakersin my living room so I decided to break them down and rebuild them. I decided to use 1/2” walnut plywood for the shell of the cabinets and 1/2” hickory for the front face. Since there is a science to the dimensions of a speaker cabinet including depth and where the bass port is, I decided to keep all the specs of the original cabinets. The only change that was made was I decided to include feet to raise them up from the floor. They are finished with a heavy coat of boiled linseed oil and couple coats of Deft spray lacquer. This is one of my favorite projects because I finally get to build something for myself that’ll enhance my living room. I think this is going to be the start of a new passion for me. That is rebuilding and upgrading things around the house with wood.

Song used at the end of the video is called Flickering and is a rough mix by my band Hound. The album’s official release is scheduled in the distant future. Be safe. Stay passionate. And make something!

Products Used

Woodworking Books

Make Your Own Cutting Boards

15 cutting board projects to make as gifts or sell! Get your signed copy!

The New Bandsaw Box Book

8 bandsaw box projects you can make and sell at craft shows. Signed copies now available!